Prepregs are preimpregnated, partially cured fabrics. These are used to produce sheet and pipe material. Through years of experience and modern machinery, we produce materials of the highest quality – for our own use or for customers to process further. A wide variety of material combinations and impregnation methods are used.

Von Roll has a broad portfolio of pre-impregnated laminates with specific properties for a wide range of industrial applications. This includes standard grades as well as highly specific solutions for special requirements. We are also happy to carry out contracted impregnation of technical fabrics for you.

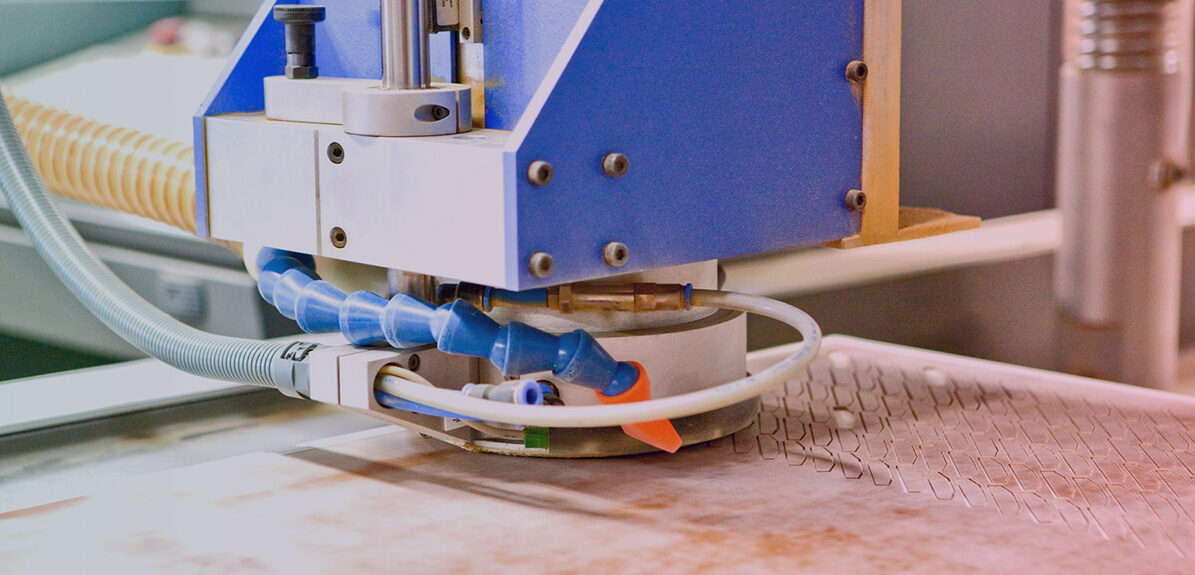

In our state-of-the-art production facilities, we use a wide variety of impregnation technologies – e.g. dip coating, kiss coating or transfer coating. Due to extra-wide impregnation lines and strictly controlled climatic conditions, we achieve the highest productivity and quality.

In order to document the best quality transparently, we can seamlessly monitor the entire process chain from the receipt of the individual raw materials, through the resin mixture, to the finished prepreg.

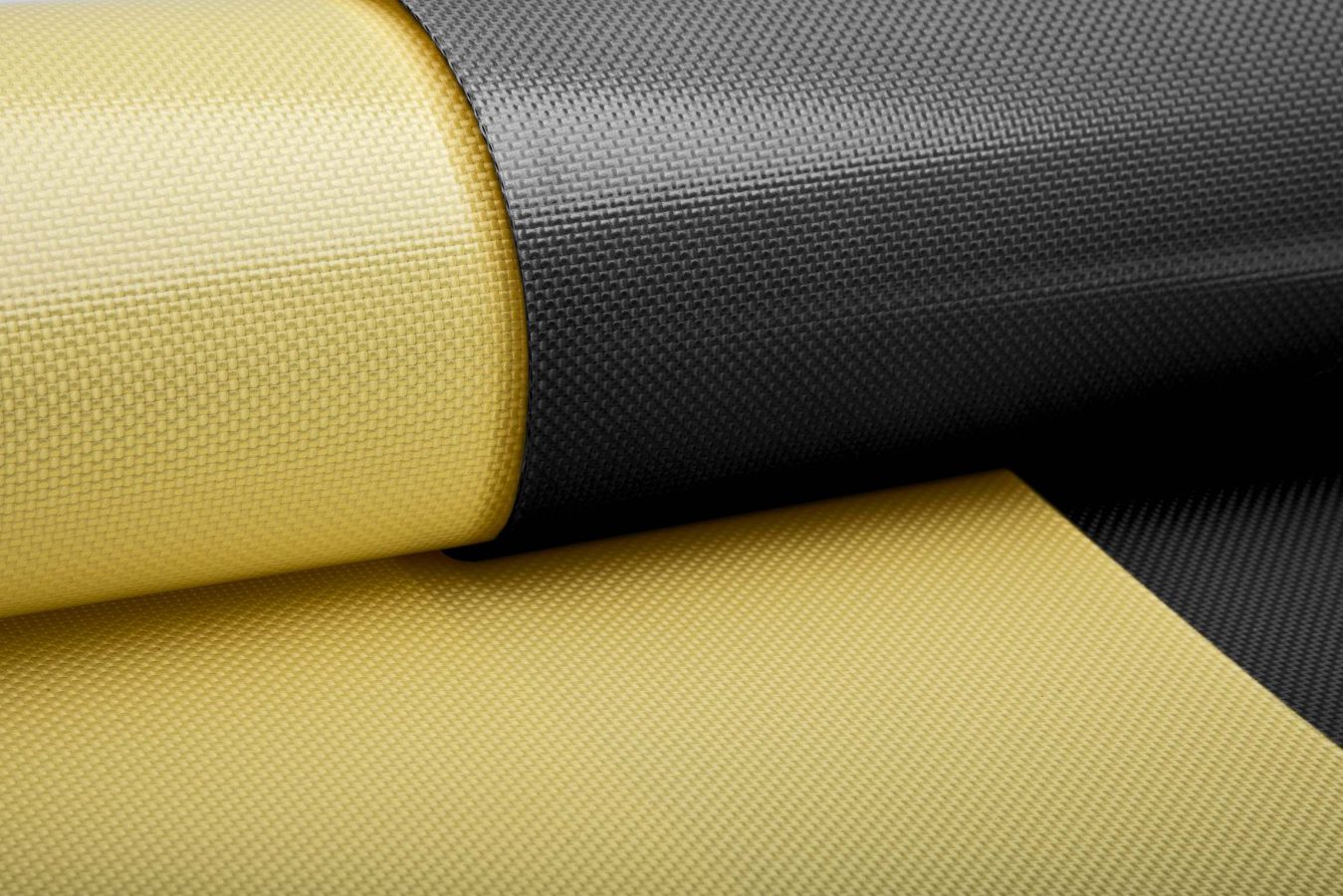

As an expert in the formulation of resins and the impregnation of technical fabrics, we offer a wide variety of prepregs – the possible combinations of different resins, fabric materials, fabric types and additives are almost endless.

The range of formulations used includes epoxy, phenolic, polyester, silicone and polyimide resins, among others. These form the matrix into which various tissue materials and types are embedded. The resins, in combination with the reinforcement, form the core of our prepregs. We use glass fabric, glass mats, cotton fabric, cellulose paper, mica paper, aramid fabric and carbon fiber fabric of various widths and qualities.